Plant-based food has evolved from a trend into a true transformation engine of food system. In this article, we explain how analogue proteins are developed, what opportunities the market is opening, and which challenges we still need to address, always framed within the rise of the plant food based diet.

Market outlook: plant-based food

Global population growth is putting sustained pressure on protein demand: animal protein is expected to increase by 52%. At the same time, social awareness and the demand for sustainable alternatives are rising, fueling the growth of the flexitarian diet.

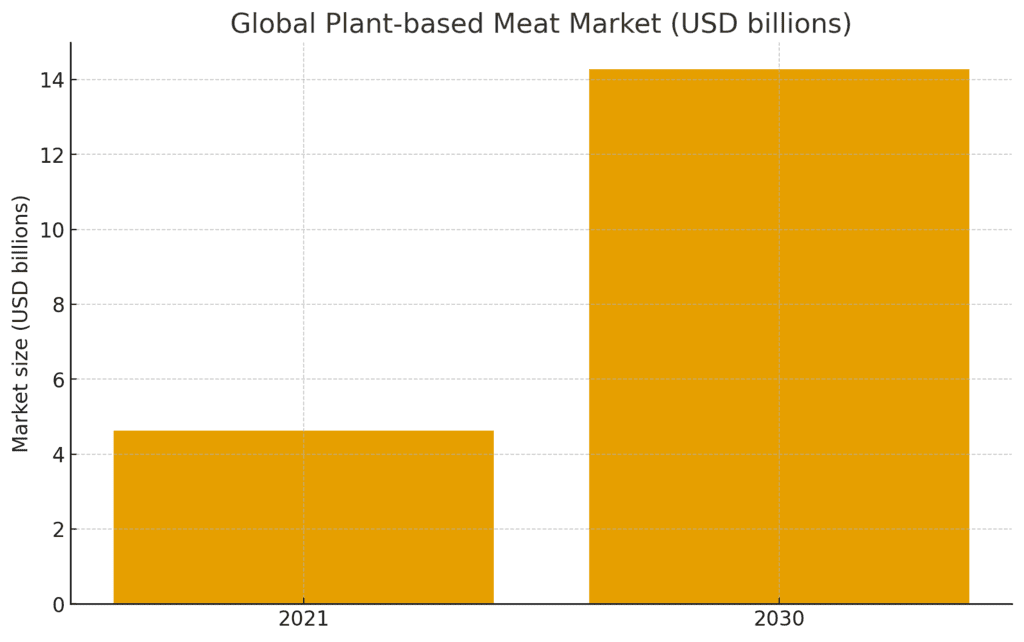

Forecasts indicate robust expansion: the global plant-based meat market is projected to grow from USD 4.62 billion in 2021 to USD 14.27 billion by 2030.

Although momentum varies by category and region, in Europe growth rates for plant-based proteins range from –0.8% to 14.9%, reflecting more mature markets in some countries and rapid expansion in others.

Challenges for the food industry

- New sources and ingredients. Broaden the toolkit with proteins, fats, flavours and bioactive compounds that add nutritional and sensory value and enable more versatile formulations.

- Animal-like techno-functionality. Develop ingredients with properties comparable to animal counterparts (emulsification, gelation, water-holding, foaming) to ensure stability and a strong eating experience.

- Advanced processes and applications. Accelerate extrusion and fermentation to create new structures and formats with greater sensory realism.

- New product development. Design fermented products and proposals tailored to specific consumer groups (children, seniors, sports, intolerances), tuning texture, flavour and nutritional density to the end use.

- Clean label. Build short, transparent ingredient lists that preserve flavour and texture.

Plant-based foods: developing animal-analogue proteins

To bring plant-based food closer to meat or fish experiences, the most widespread route is extrusion. This process subjects protein blends to heat, pressure and shear to reorganise their chains and generate fibrous structures. There are two main approaches, each with distinct products and uses.

- With low-moisture extrusion, we obtain classic textured vegetable protein (TVP). The result is a dry, ambient-stable, highly versatile ingredient designed to be rehydrated before cooking. It leverages a wide array of sources—pea or soy concentrates and isolates, gluten, lentil, faba bean, sunflower, among others—and can be combined with alternatives such as microalgae, mycoprotein or even insect flours. In the kitchen, rehydrated TVP performs well as mince, strips or cubes in fillings, sauces, prepared dishes or extrusion snacks. Its key advantages are logistical: long shelf life, competitive cost and consistent performance across multiple matrices.

- With high-moisture extrusion (HMEC) the goal shifts to long, aligned fibres that mimic meat striation. The product exits the extruder wet and unexpanded, with a more realistic, juicy texture that does not require rehydration; therefore it is sold chilled or frozen. The protein base is similar to TVP—soy and pea isolates or concentrates—with the option to integrate other alternative sources to tune functionality, nutrition or labelling. Again, starches, fibres, salt and flavour/colour modulators help refine bite, water retention and appearance. HMEC’s advantage lies in the sensory experience.

From an innovation standpoint in plant-based proteins, choosing between TVP and HMEC depends on product positioning and the value equation. In both cases, success relies on combining the right protein matrix with the right minor ingredients and a finely calibrated process to balance techno-functionality, nutritional profile, flavour and the cleanest possible label.

Plant-based foods: developing dairy analogues

For plant-based food to compete with dairy equivalents, products should deliver:

-

Flavour, colour and odour close to neutrality

-

Techno-functional performance tailored to each application

-

A strong nutritional profile: proteins, quality lipids and micronutrients

-

Compatibility with processes such as fermentation

-

Stability in complex formulations without phase separation

The development of plant-based dairy analogues rests on four technological levers: fermentation, homogenisation, thermal/enzymatic treatments, and ingredient selection/regulatory feasibility. Used together, these levers enable clean-label products with stability and a sensory experience close to animal dairy.

Fermentation technologies for dairy analogue development

-

Traditional fermentation: delivers the final product (e.g., yoghurt/cheese analogues) from plant beverages using selected starters.

-

Biomass fermentation: produces intermediate products such as single-cell protein (mycoprotein) and postbiotics, useful for reinforcing texture, nutrition and stability.

-

Precision fermentation: enables advanced ingredients, recombinant proteins or fats and other compounds (flavours, enzymes, vitamins, etc.) that replicate key dairy functions.

Plant-based food has firmly established itself as a real lever for transformation. The ongoing challenge is to integrate all consumer expectations into a balanced proposition. To achieve this, we must broaden the range of sources, sharpen their techno-functional performance and scale processes such as extrusion and fermentation. If we align science, process and regulation, the next generation of plant-based foods within the plant food based diet will not only be an alternative—it will become the preferred choice for performance, health and sustainability.