Did you know that the defatted cocoa you’re used to still contains around 10% fat? What if we told you that advanced technologies now make it possible to reduce this content to less than 1%? Through supercritical dioxide (CO₂) extraction, it is possible to obtain ultra-defatted cocoa with minimal fat, high fibre content and bioactive compounds, making it an ideal ingredient for dietary and functional applications. In this article, we explain how this technology works, how it differs from conventional methods, and why it can make a real difference to your products.

Obtaining pure defatted cocoa using supercritical CO₂

Defatted cocoa is an ingredient obtained through controlled reduction of its fat content. Compared to traditional mechanical pressing methods, a more advanced and sustainable alternative is extraction using carbon dioxide (CO₂) in its supercritical state. This clean technology enables selective removal of the lipid fraction without using organic solvents, preserving valuable bioactive compounds and resulting in a purer, safer and more stable ingredient.

Supercritical CO₂ extraction is carried out using the defatted cocoa cake obtained after pressing. This allows the fat content to be further reduced to values below 1%. The result is an extremely low-fat cocoa powder with a higher concentration of dietary fibre, plant-based proteins and polyphenolic compounds.

What are the properties of pure defatted cocoa?

Defatted cocoa obtained through supercritical CO₂ extraction offers an optimised nutritional profile alongside excellent functional and sensory behaviour. Its ultra-low fat content — below 1% — makes it a high-value dietary ingredient, with up to 10 times less fat than conventionally defatted cocoa.

Key properties include:

- Very low fat content, significantly reducing caloric value and making it ideal for functional or energy-controlled formulations.

- High dietary fibre, both soluble and insoluble, supporting digestive health, intestinal transit and glycaemic control.

- Source of plant-based protein, suitable for balanced diets, sports nutrition and plant-based applications.

- Rich in essential minerals such as magnesium, iron and potassium, contributing to the nutritional quality of the end product.

- High polyphenol content, especially flavonoids, offering antioxidant activity that helps combat oxidative stress.

- Intense colour and aroma, preserved thanks to a solvent-free extraction process that retains key flavour compounds.

- Oxidative stability, due to minimal fat content, supporting extended shelf life in final products.

Conventional defatted cocoa vs. ultra-defatted cocoa by supercritical CO₂

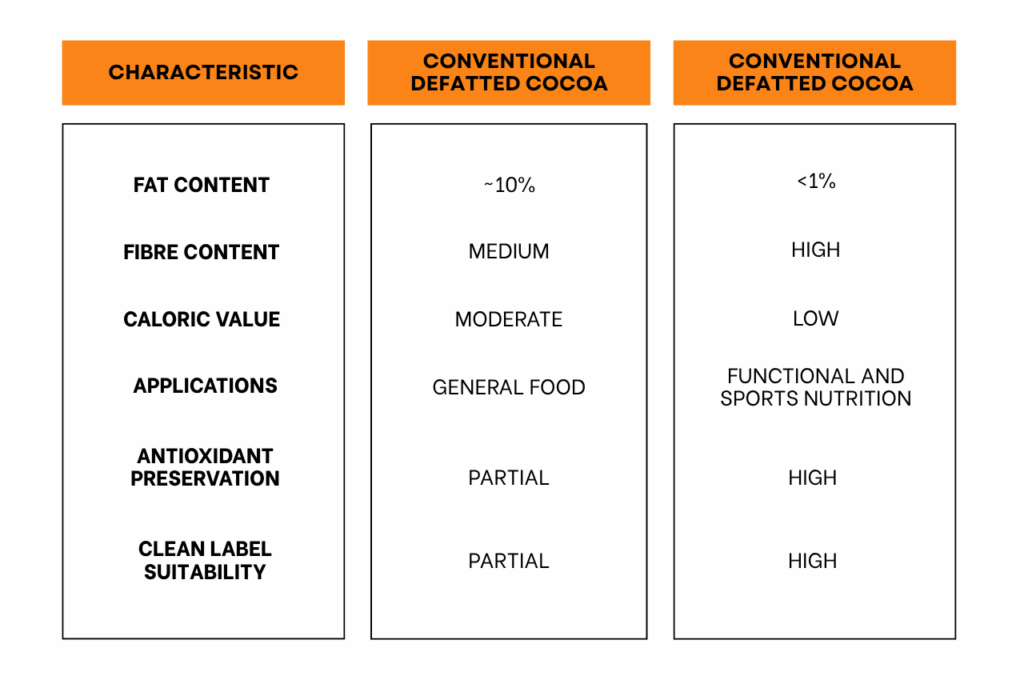

Most commercially available defatted cocoa is produced via mechanical pressing, which results in a fat content of approximately 10–12%. While suitable for many applications, it retains a significant lipid fraction.

In contrast, cocoa defatted using supercritical CO₂ is an “ultra-defatted” version of the product, with as little as 1% fat. This key difference has significant implications in terms of nutritional profile, functionality and application range.

Applications of pure defatted cocoa

Thanks to its unique properties, supercritically defatted cocoa is especially valued in:

- Low-fat bakery and confectionery

- Sports and functional nutrition

- Shakes, bars and healthy desserts

- Nutritional supplements and natural flavour systems

- Plant-based and weight management products

Benefits of supercritical CO₂ extraction technology

Beyond the ingredient itself, the use of supercritical CO₂ extraction brings added value at an industrial level:

- Selective compound targeting, preserving only the most valuable cocoa components.

- Clean and safe process, free from toxic solvents or chemical residues.

- CO₂ recovery and reuse, supporting circular economy principles and environmental sustainability.

- Greater purity, facilitating integration into clean label formulations.

- Low-temperature processing, protecting thermosensitive compounds such as polyphenols.

Widely used for the defatting of natural products like coffee, herbs, seeds or essential oils, this technology represents a clear commitment to quality, innovation and sustainability in ingredient processing.