Cultivated meat is becoming a key innovation lever to move towards more sustainable, resilient and efficient food systems. In this context, within the MEAT4FUTURE project we have generated applied knowledge and technological results that bring cultivated meat closer to industrial reality, strengthening process safety, reproducibility and scalability.

MEAT4FUTURE has been supported by IVACE and FEDER and developed in collaboration with Industrias Grau and Embutidos Martínez, with the aim of providing companies with new methodologies and tools to innovate in the field of alternative proteins.

Through MEAT4FUTURE, we have taken a further step towards transferring cultivated meat to an industrial environment. We have worked on improving the quality, efficiency and scalability of the processes involved, while advancing in the generation and characterisation of bovine cell cultures, assessing their growth, differentiation and safety, with a clear objective: to equip companies with new capabilities to innovate in alternative proteins.

Cultivated meat: Safety and reproducibility of the cellular ingredient

One of the key challenges of cultivated meat is ensuring that the cellular ingredient is developed under safe and consistent conditions. Within the project, we identified relevant risks and defined control and prevention measures.

In our trials, we verified the absence of contaminants in bovine cell cultures after successive subcultures performed without antibiotics, reinforcing the robustness of the process. In addition, we analysed reproducibility in primary cultures, particularly adipose cells, confirming the importance of evaluating each sample individually to ensure consistent behaviour and differentiation potential.

Edible scaffolds based on alternative protein sources

To move closer to more realistic product formats, we worked on the development of edible scaffolds based on alternative proteins. Texturised structures were obtained by extrusion from different plant-based and microbial raw materials, and the most promising options were selected for validation as cell growth scaffolds.

The trials showed that, when cellular growth is incorporated, attributes such as juiciness and texture are enhanced, and a more perceptible meaty aroma emerges, especially after cooking. These advances were shared at an international scientific forum within the sector, reinforcing the visibility of the project.

Cultivated meat: More efficient and scalable processes

Another core pillar of the project focused on progressing towards more efficient and scalable processes. We worked on cell expansion and handling strategies aimed at improving productivity and defining criteria relevant for industrial scale-up, with a strong emphasis on operational robustness and process reproducibility.

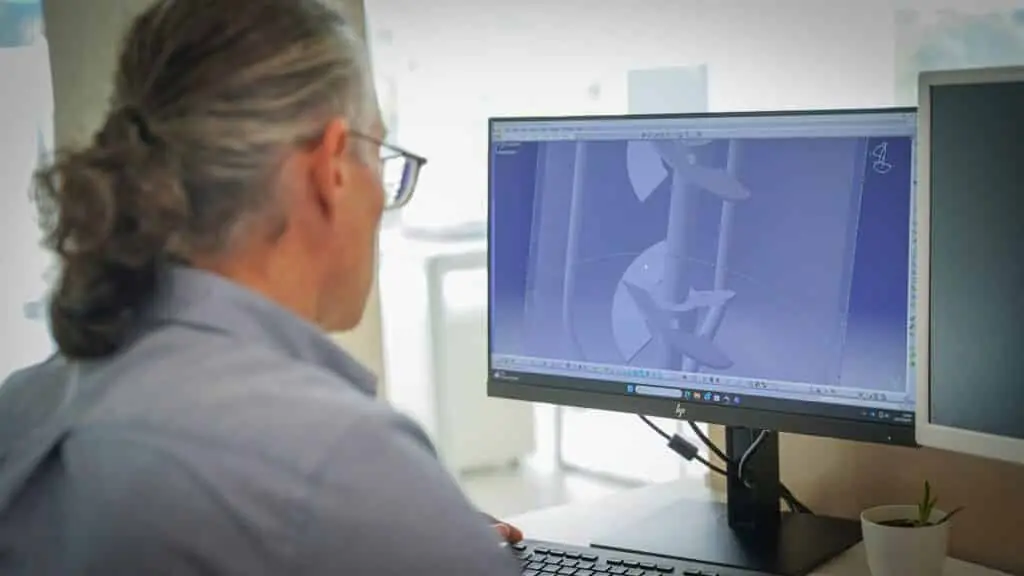

Bioreactor optimisation through CFD simulations

We also generated key results to optimise bioreactor design and operation using CFD (Computational Fluid Dynamics) simulations. This approach enabled us to analyse mixing and oxygen availability, identifying opportunities to improve process homogeneity and minimise zones with less favourable conditions.

The work highlights the importance of aeration system design and of balancing adequate oxygenation with a gentle hydrodynamic environment, which is particularly critical for sensitive cell cultures.

Prototypes and product validation of cultivated meat

Finally, we addressed post-processing to obtain model portions and product prototypes. We evaluated biomaterial formulations for 3D bioprinting to simulate “steak-like” structures and, in parallel, developed hybrid burgers, comparing 100% plant-based formulations with formulations incorporating cultivated meat.

The results demonstrate technological advantages in hybrid formulations, particularly in terms of compaction, cohesion and structural integrity after cooking. We also identified the need to fine-tune thermal parameters to avoid excessive browning. From a sensory perspective, the overall profile remained similar, with a predominance of plant-based notes, opening up improvement pathways aimed at reinforcing the meaty character without compromising consumer experience.

Cultivated meat as a functional ingredient for hybrid matrices

Overall, the results of MEAT4FUTURE confirm the technological feasibility of cultivated meat as a functional ingredient in hybrid matrices and provide relevant advances in safety, processing, scalability and prototype development. At AINIA, this work reinforces our positioning as a technology partner for industry in the development of innovative and sustainable solutions in the field of new proteins.

The MEAT4FUTURE project has enabled AINIA to advance in the development of key knowledge and technological capabilities to drive cultivated meat from a safe, scalable and industrial perspective. The results obtained underline the role of R&D&I as a driver to address food system challenges and facilitate the transfer of innovative solutions to the business ecosystem.

This initiative was supported by the Conselleria d’Innovació, Indústria, Comerç i Turisme of the Generalitat Valenciana, through IVACE, and co-funded by the European Union via the FEDER Comunitat Valenciana 2021–2027 Programme, contributing to the positioning of the Valencian Community at the forefront of alternative protein research and the development of more sustainable production models.