Subscribe to our newsletter

- R&D&I Programmes

- Technological Services

- Consultancy Services

- Laboratory Services

- Training and Events

- Sectors

Circular and sustainable economy concepts have become deeply embedded in both our social mindset and industrial practices. Increasingly, industries are striving to protect the environment while also maximizing economic returns. This shift in priorities has led to a new paradigm: one where value is extracted from what was once considered waste. In the case of agri-food waste, this shift is especially significant. Hidden within these by-products lies a treasure trove of valuable compounds, but how can we unlock it?

Selective fat removal is a strategic technology applied to plant-based matrices and food industry by-products aimed at developing functional food formulations. At AINIA, supercritical CO₂ is used to reduce fat content to levels below 1%, while preserving the extraction of natural lipid fractions without the use of organic solvents. This process allows for the creation of low-fat food ingredients suitable for sports or dietetic products, maintaining protein structure and functionality, and eliminating unwanted odors without chemical residues.

Several non-cellulosic fractions present in agrifood waste such as pectins, polyphenols, soluble proteins, and polysaccharides, can be transformed into functional compounds for food and nutraceutical applications. The selective extraction of these bioactive components, followed by the purification of cellulose, leads to the production of ingredients enriched in antioxidants, soluble fiber, or bioactive peptides. Additionally, recovered lignin holds potential for use in antioxidant or antimicrobial formulations.

When discussing the reuse of by-products and agri-food waste, it is essential to highlight the role of biorefineries. The agri-food industry generates vast volumes of residues and by-products during food processing operations or agricultural activities. On the agricultural side, these include rice, barley, wheat, and oat straw; corn stalks; rice husks; nutshells and skins; pruning residues; and green waste from greenhouses, among others. These materials often hold little to no economic value—at best, they are used for animal feed, and at worst, they are burned in an uncontrolled manner, contributing significantly to pollution.

Other processed residues, such as brewers’ spent grain, citrus peels and pulp, sugar beet residues, and general fruit and vegetable waste, also represent a serious challenge for the processing industry. What all of these agri-food waste materials share is a high lignocellulosic content—that is, they are primarily composed of cellulose and lignin.

The key lies in the proper extraction of non-cellulosic components, mainly pectins, proteins, and other extracts, and/or in the delignification of the raw material, depending on the chemical composition of each by-product. This is followed by the purification of the cellulose. On one hand, this allows for a high-purity cellulose to be obtained; on the other, it enables the recovery of lignin and other valuable compounds such as bioactives or polyphenols.

At AINIA, we are developing environmentally friendly extraction and purification processes tailored to the nature of each residue, ensuring no harmful waste is generated.

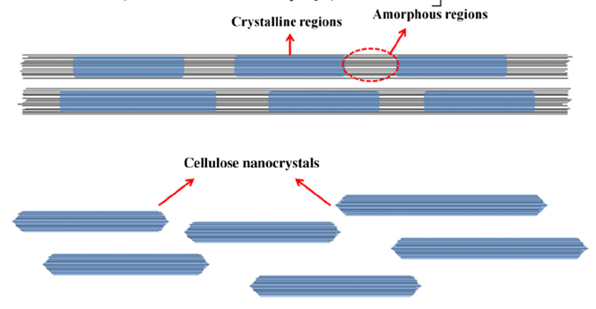

The term “micro and nanocellulose” includes both microfibrillated cellulose (MNFC) and cellulose nanocrystals (CNC). MNFC consists of long, flexible fibers with both amorphous and crystalline regions, while CNCs are shorter, rigid structures lacking the amorphous component.

Figura 2. Estructura microfibras de celulosa y nanocristales de celulosa. Fuente: Alle et al. 2020.

There is a growing demand in the packaging industry for alternatives to conventional plastics—materials that are fully biodegradable and compostable. At AINIA, we are developing new coatings based on modified MNFCs with enhanced hydrophobic properties and improved barriers to oxygen and fats.

Bulk application (on cellulose-based packaging): When applied to molded cellulose or paper packaging, MNFCs act as a reinforcing agent, improving the mechanical properties of the final product.

Bulk or filler use (with other biopolymers such as PLA or PHAs): This helps improve the overall performance of final products and reduces the amount of raw material required—not only for food packaging but also for biocomposites in a wide range of industrial sectors.

One of AINIA’s goals is to identify natural alternatives to synthetic materials for microencapsulation. For this reason, we are using MNFC—and, more broadly, micro and nanocellulose—as biodegradable coating agents in the production of microcapsules.

One of the unique properties of MNFC is its ability to form viscous gels even at low concentrations (1–3%) in aqueous suspensions. This makes it an excellent rheology modifier. Additionally, market opportunities in the cosmetics sector include its use as a hydrating agent and emulsifier.

This initiative is funded by IVACE (Valencian Institute for Business Competitiveness) under its collaboration agreement with AINIA to support R&D&I activities with industrial transfer potential.

| Responsible | AINIA |

| Address | Calle Benjamín Franklin, 5 a 11, CP 46980 Paterna (Valencia) |

| Purpose | To attend to, register and contact you to resolve the request you make to us through this contact form |

| Legitimation | Your data will be processed only with your consent, by checking the box shown on this form |

| Recipients | Your data will not be transferred to third parties. |

| Rights | You have the right to request access to, correct or delete your data. You can also request that we limit its processing, oppose it and request the portability of your data by contacting our postal address or [email protected] |

| More info | You can find more information in our Privacy Policy |

| DPO | If you have any questions about how we will treat your data or would like to make any suggestions or complaints, please contact the Data Protection Officer at [email protected] or at the Data subject support form |

I consent to the use of my personal data to process my request, as set forth in your Privacy Policy

I consent to the use of my data to receive information and commercial communications from your entity.