AINIA digital

TERMOSEAL: Perfect sealing on each package, guaranteeing quality and food safety.

Perfect sealing on each package, guaranteeing quality and food safety.

A new standard in the inspection of heat-sealed plastic packaging

It detects visible and invisible defects to ensure the quality of your production

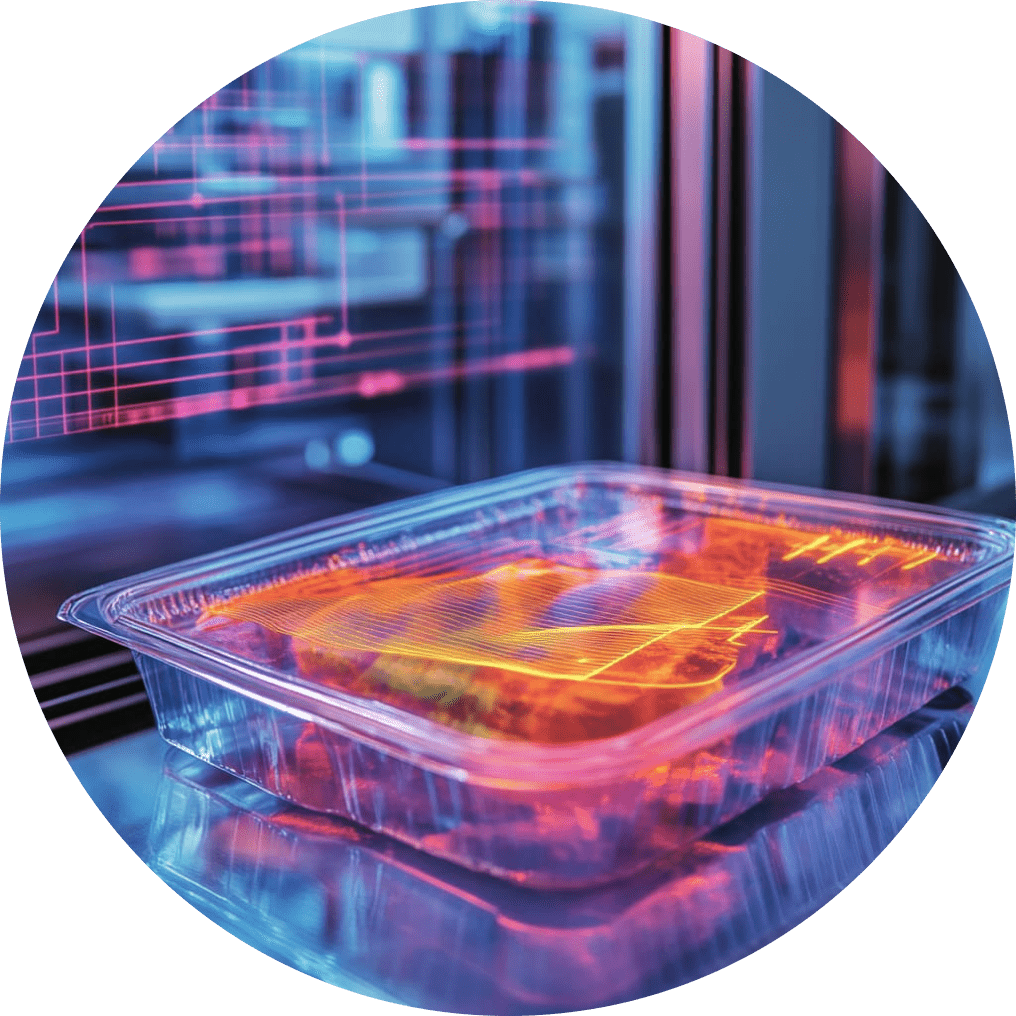

Companies using heat-sealed plastic packaging face significant challenges related to sealing quality and safety. Invisible defects, such as weak seals, residues in the welding zone or undetected leaks, can compromise not only the product, but also customer trust and brand reputation.

TERMOSEAL is AINIA’s patented solution that uses advanced thermography and artificial intelligence to continuously inspect 100% of the produced packages . Unlike traditional solutions that rely on sampling inspections or invasive techniques, TERMOSEAL ensures precise control without interrupting the production line.

Why is it important?

- Poor welding can lead to leaks, contamination and financial losses.

- Manual visual inspections or those based on conventional vision do not detect internal defects.

- TERMOSEAL provides real-time data to correct problems before they affect the entire production.

Discover our video

Beyond traditional inspection: efficiency and reliability

Innovation that protects your product and your brand

TERMOSEAL offers multiple benefits that not only optimize production, but also raise quality standards in the food industry:

Thorough inspection

Evaluate 100% of the produced packages , without the need for sampling.

Accurate detection

It identifies visible defects (residues, seal failure) and invisible defects (weak seals or internal inconsistencies).

Reduction of operating costs

Reduce refunds, claims and losses due to defective batches.

Maintenance optimization

Real-time problem detection helps identify and resolve faults in the heat-sealing machinery.

Generation of quality data

It allows analysis by batch, packaging type and work shift, facilitating traceability and continuous control.

Why choose Termoseal?

- Accurate inspection of 100% of the containers, without the need for interruptions or costly adjustments.

- It detects invisible defects such as weak seals, ensuring higher product quality.

- Cost-effective operation and adaptable to various references and packages formats.

- Exclusive patented technology that ensures regulatory compliance and market leadership.

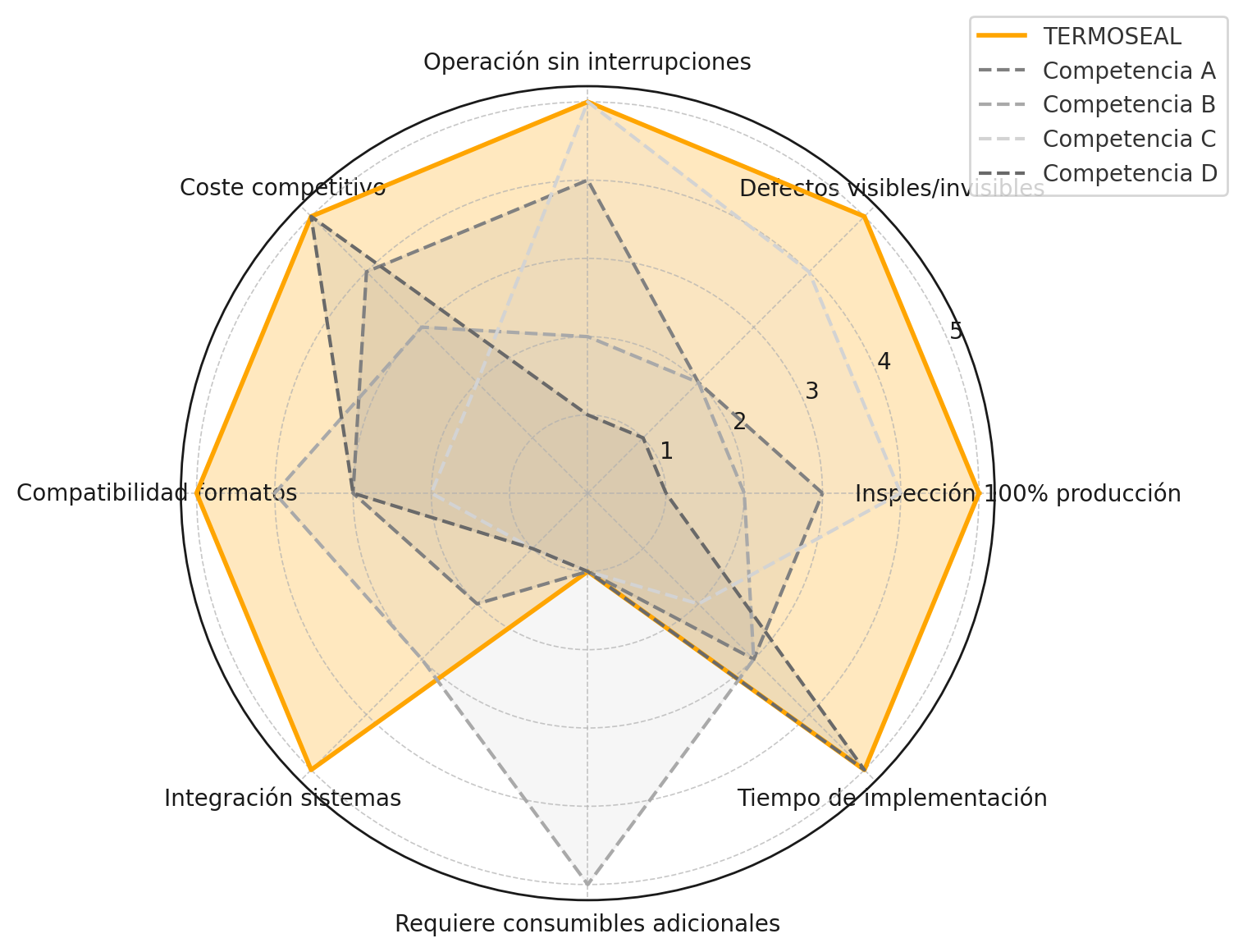

| Features | TERMOSEAL | Competence A (Basic Vision) | Competence B (Basic Thermography) | Competence C (Hyperspectral Vision) | Competence D (Manual Methods) |

|---|---|---|---|---|---|

| 100% production inspection | Yes | Yes | Yes | Yes (but at high cost) | No (limited sample) |

| Detection of visible and invisible defects | Yes | No (only visible) | No (only visible) | Yes (but not profitable) | No (only visible) |

| Uninterrupted online operation | Yes | Yes | No (requires stopping production) | Yes | No (very slow and dependent on humans) |

| Affordable and competitive cost | Yes | Yes | Yes | No (high cost) | Yes (but not very efficient) |

| Support for multiple formats | Yes (trays, flow-pack, doypack) | Yes (limited to some formats) | Yes (but with functional limitations) | No (product specific settings) | Yes |

| Integration with existing systems | Yes | No | No | No (high complexity) | No |

| Requires additional gases or consumables | No | No | Yes (makes the operation more expensive) | No | No |

| Implementation time | Short | Moderate | Moderate | Long | Short |

03_ Technology

Artificial intelligence and thermography in pursuit of perfection

The difference is in the patented technology

TERMOSEAL combines three advanced technologies to provide a unique solution:

Thermography

Thermography

Thermography

Thermography It uses high-precision thermal sensors to identify variations in sealing temperature, detecting defects invisible to the human eye

Machine vision

Machine vision

It captures high-resolution images to visually assess the quality of welds, detecting residues or external deformations.

Artificial intelligence

Artificial intelligence

Artificial intelligence

Artificial intelligence Machine learning algorithms analyze complex patterns and differences in welds, continuously improving their accuracy.

Technological advantages

- Real-time inspection without interrupting the production.

- Adaptation to different packaging formats (trays, flow-pack, doypack).

- Assurance of compliance with food safety and quality standards.

- Advanced technology to distinguish different defects according to their severity.

- Opportunity of adding other quality control systems through artificial vision.

Proven results across multiple sectors

Tangible results that prove how TERMOSEAL revolutionizes quality and safety across diverse industries

Each TERMOSEAL implementation has enabled our customers to reduce operating costs, minimize returns and strengthen consumer confidence.

TERMOSEAL has proven its effectiveness in various industrial applications:

Meat industry

Meat industry

Meat industry

Meat industry It detects faults in fresh and processed meat trays, ensuring hermetic packaging.

Nuts and dried fruits

Nuts and dried fruits

Nuts and dried fruits

Nuts and dried fruits Inspection of flow-pack bags to ensure sealing.

Seafood products

Seafood products

Seafood products

Seafood products It prevents leaks in fish and seafood trays.

Ready meals

Ready meals

Ready meals

Ready meals It ensures the quality of heat-sealed packages for ready-to-eat meals.

Horticultural

Horticultural

Horticultural

Horticultural It detects faults in the thermosealing of lettuce and salad.

Bakery

Bakery

Bakery

Bakery Ejection of pancake bags that do not meet sealing quality standards.

Backed by experience and innovation

Leading companies rely on TERMOSEAL to guarantee excellence in every package.

AINIA has been leading the digital transformation and innovation in the food sector for years. Leading food companies trust TERMOSEAL to guarantee the quality of their processes, backed by our patented technologies and success stories in different sectors.

Leading companies rely on TERMOSEAL to guarantee excellence in every package.

An investment that pays offf from day one

TERMOSEAL not only improves product quality, but also optimizes operating costs and increases productivity:

- Reduction of waste

It detects defects in real time, before they affect large volumes.

- Improved maintenance

Maintenance control thanks to real-time detection of problems such as cold claws.

- Reduction of claims

It improves customer perception and reduces costs associated with refunds.

- Increased efficiency

Real-time data enables immediate production adjustments.

- Modularity

Multiple machine vision quality control systems can be incorporated into the same inspection point.

You may be interested in

Robotization and automation

Robotics and predictive systems for resource management and optimization

Environment monitoring and analysis systems, collaborative platforms and chain management.

FoodAlert

07_ Contact us

Carlos Fernandez

Business Development

How can we help you?

Carlos Fernandez

Business Development

Basic information on data protection

Responsible

AINIA

Address

Street Benjamín Franklin, 5 a 11, CP 46980 Paterna (Valencia)

Purpose

To attend, register and contact you in order to solve the request you make through this contact form.

Legitimation

Your data will be processed only with your consent, by ticking the box shown in this form.

Addressees

Your data will not be disclosed to third parties

Rights

More information

More information is available in our Privacy Policy.

DPD

If you have any doubts about how we will treat your data or you would like to make a suggestion or complaint, please contact the Data Protection Officer at [email protected] or by filling out the form for the attention of the interested party.