AINIA digital

Digital Food Factory: Optimize processes and improve quality with AI-based predictions

Optimize processes and improve quality with AI-based predictions

A new perspective for your business

Integrates processes, optimizes resources and assures product quality

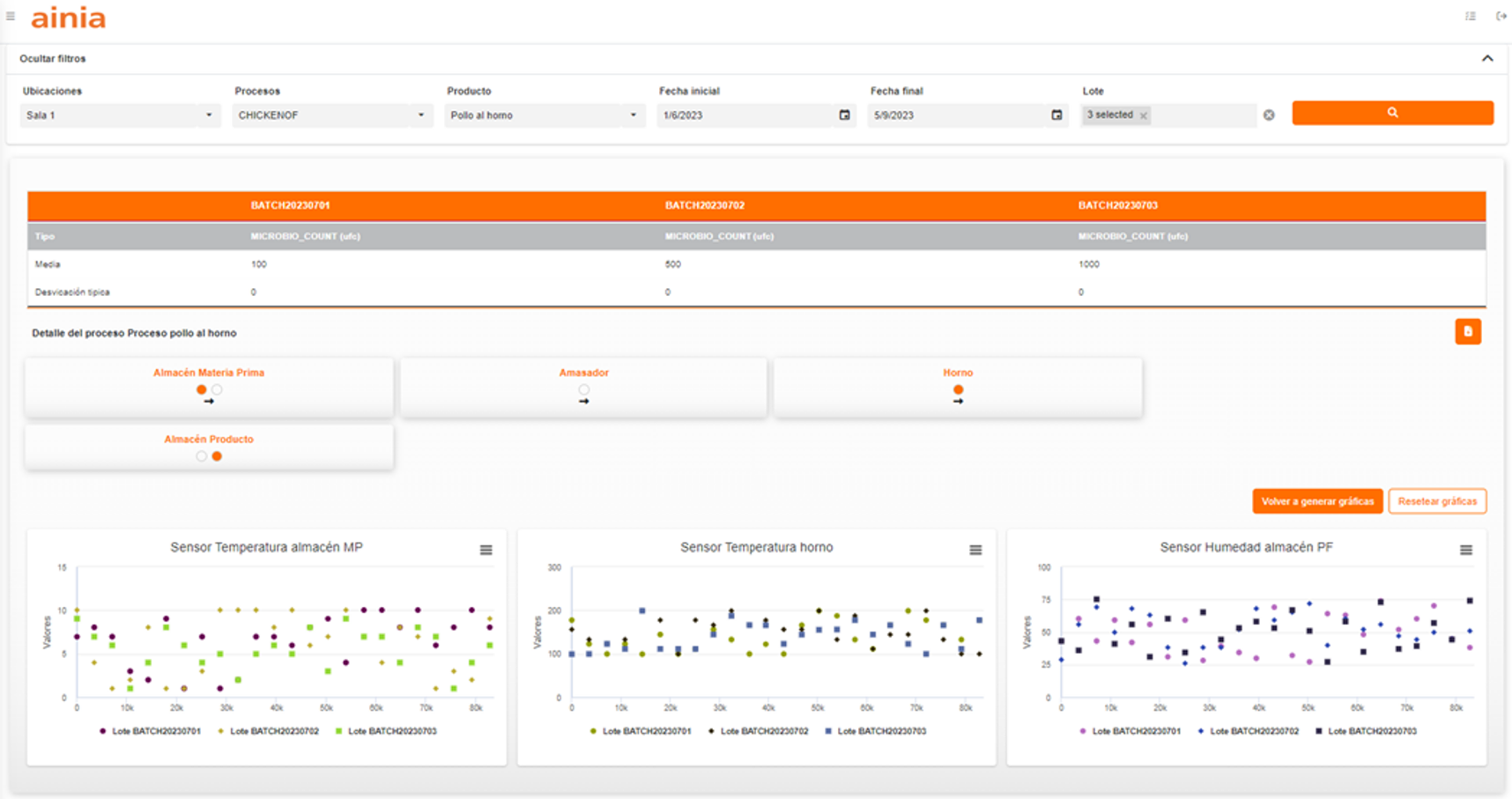

The food industry faces constant challenges: quality control, energy efficiency and waste reduction. Digital Food Factory addresses these needs by connecting process and product variables through artificial intelligence. Its predictive capabilities identify opportunities before problems arise, helping you make data-driven decisions.

Discover how it works

Data-driven decisions for guaranteed results

Transform your production processes with state-of-the-art technology.

Data-driven decisions

Reducing uncertainty and increasing the probability of success.

Process optimization and product improvement

By improving efficiency, reducing waste, and ensuring consistency of final product quality.

Customization and adaptability

They ensure the solution remains effective despite changes in production or market demands.

Automation of complex tasks

It frees employees to focus on more strategic, higher-value tasks.

Innovation that drives your factory

Boost your production with AI and real-time analytics

Digital Food Factory combines advanced technologies to offer a unique solution:

- Artificial Intelligence (AI)

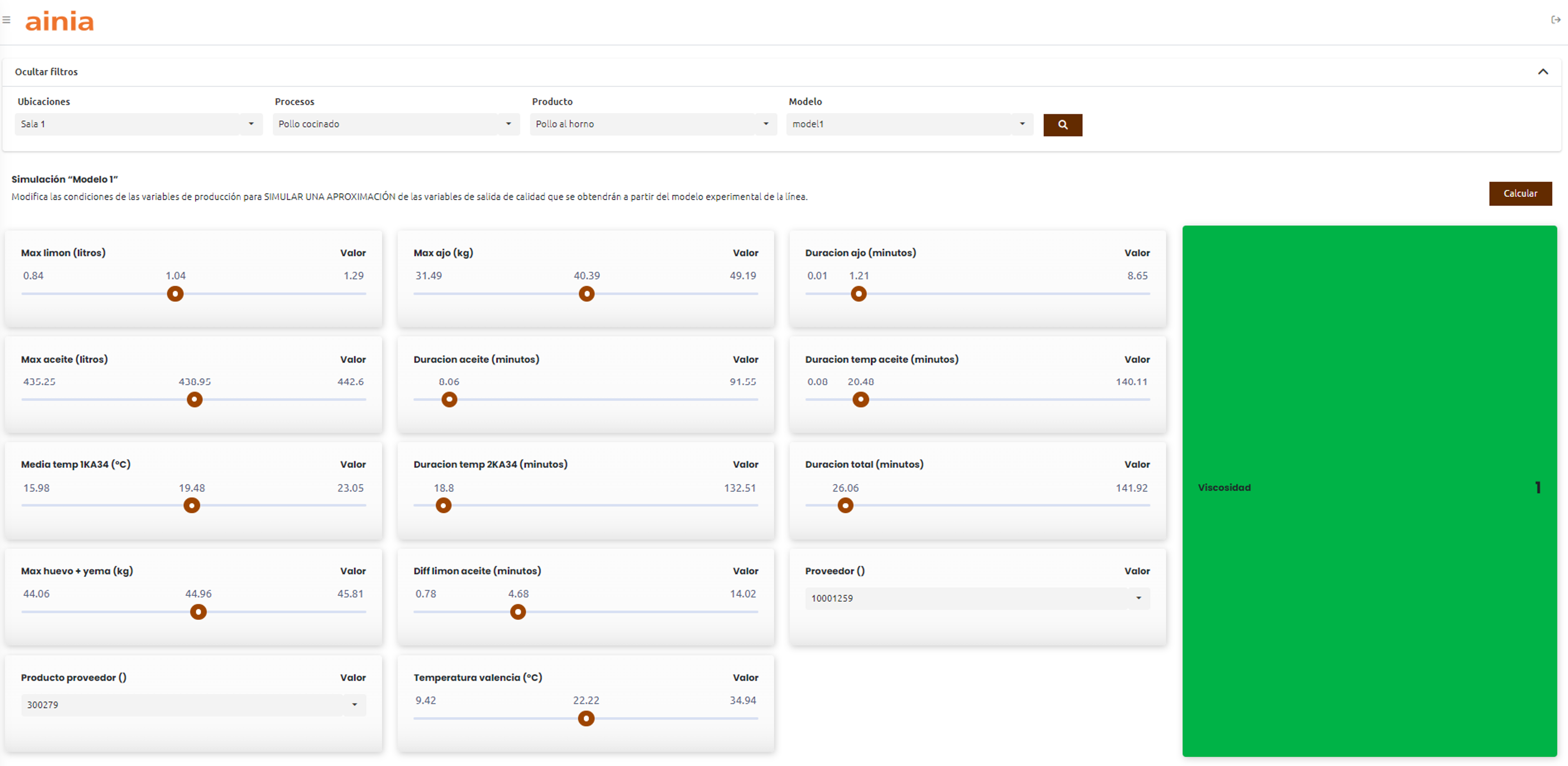

Predictive models to identify hidden patterns and trends.

- Machine Learning

Algorithms that adapt and improve with new data.

- Big Data

Real-time processing of large volumes of data.

- Edge Computing

Immediate analysis without compromising production efficency.

- IoT Integration

Direct connection to existing sensors and management systems.

| Features | Digital Food Factory | Competence A | Competence B |

|---|---|---|---|

| AI-based predictions | Yes | Limited | No |

| Real-time optimization | Yes | No | No |

| Continuous scalability | Yes | Limited | Limited |

Smooth implementation

Tailored to your needs.

The implementation of Digital Food Factory is agile and scalable:

- Compatible with existing ERP and MES systems.

- Scalability to grow with your needs.

- Personalized technical support to ensure continued success.

Stories behind our solution

Real results, tangible impact

Leading companies have experienced the impact of Digital Food Factory:

Nuts and dried fruits

Nuts and dried fruits

Nuts and dried fruits

Nuts and dried fruits 20% reduction in production costs due to accurate forecasts.

Sauces

Sauces

Sauces

Sauces Real-time adjustments that ensure uniform texture.

Pastry shop

Pastry shop

Pastry shop

Pastry shop 30% increase in customer satisfaction with consistent products.

Guaranteed return

Smart investment with immediate results.

Thanks to Digital Food Factory, companies have achieved:

- 25% less in production costs

- 30% improvement in product quality.

- 20% less downtime.

You may be interested in

Robotization and automation

Robotics and predictive systems for resource management and optimization

Environment monitoring and analysis systems, collaborative platforms and chain management.

FoodAlert

08_ Contact us

Carlos Fernandez

Business Development

How can we help you?

Carlos Fernandez

Business Development

Basic information on data protection

Responsible

AINIA

Address

Street Benjamín Franklin, 5 a 11, CP 46980 Paterna (Valencia)

Purpose

To attend, register and contact you in order to solve the request you make through this contact form.

Legitimation

Your data will be processed only with your consent, by ticking the box shown in this form.

Addressees

Your data will not be disclosed to third parties

Rights

More information

More information is available in our Privacy Policy.

DPD

If you have any doubts about how we will treat your data or you would like to make a suggestion or complaint, please contact the Data Protection Officer at [email protected] or by filling out the form for the attention of the interested party.