AINIA digital

NIRSpector: Optimize processes and ensures quality with advanced real-time spectroscopy technology.

Optimize processes and ensures quality with advanced real-time spectroscopy technology.

The essence of your product, revealed

NIRSpector ensures an exhaustive control without destroying samples, optimizing your processes.

NIRSpector transforms how you monitor and characterize your production in real time. Specifically designed for the food, cosmetics, and chemical industries, it delivers accurate, non-destructive chemical analysis—reducing time, waste, and production errors.

Rapid and non-destructive analysis of 100% of the production.

Immediate reduction of waste and reaction times.

Decrease in laboratory workload.

Continuous process improvement through machine learning.

Seamless integration with your management systems (MES, ERP).

Why choose NIRSpector?

NIRSpector positions itself as a comprehensive, reliable, and scalable solution, designed to maximize operational efficiency and minimize production costs, becoming a strategic choice for companies seeking innovation.

| Features | NIR Spector | Other solutions |

|---|---|---|

| Yes | Partial | |

| Non-destructive analysis | Yes | No |

| Real-time adjustments | Yes | Limited |

| Data privacy guaranteed | Yes | No |

| Competitive cost | Yes | No |

| Adaptability to different production lines | Yes | Limited |

| Integrated machine learning | Yes | No |

- Coverage of 100% of Production

NIRSpector ensures continuous analysis of all products, in contrast to other solutions that only assess partial samples.

- Non-destructive analysis

Unlike traditional methods that damage samples, NIRSpector performs a complete analysis without affecting the integrity of the product.

- Real-time adjustments

It enables production processes to be optimized instantaneously, whereas alternatives often have limitations in this capability.

- Data privacy guaranteed

NIRSpector ensures that the data remains under your full control, without the need to share information with third parties.

- Competitive cost

It offers an ideal balance between price and benefits, standing out for its accessibility compared to more expensive options.

- Adaptability to different production lines

Its modular and flexible design allows it to be easily integrated into multiple sectors and product types.

- Integrated machine learning

NIRSpector is continuously improved by artificial intelligence algorithms, providing increasingly accurate results.

Photonics and Artificial Intelligence at the service of quality

Discover how NIRSpector redefines quality control

Discover how NIRSpector redefines quality control

NIR spectroscopy

The interaction of the penetrating light with the product material allows the detection of chemical properties without damaging the product.

Machine Learning

It identifies patterns and offers predictive adjustments.

IoT and Edge Computing

Real-time analysis with capacity for integration into industrial systems.

Modular software

Adaptable to any type of production line.

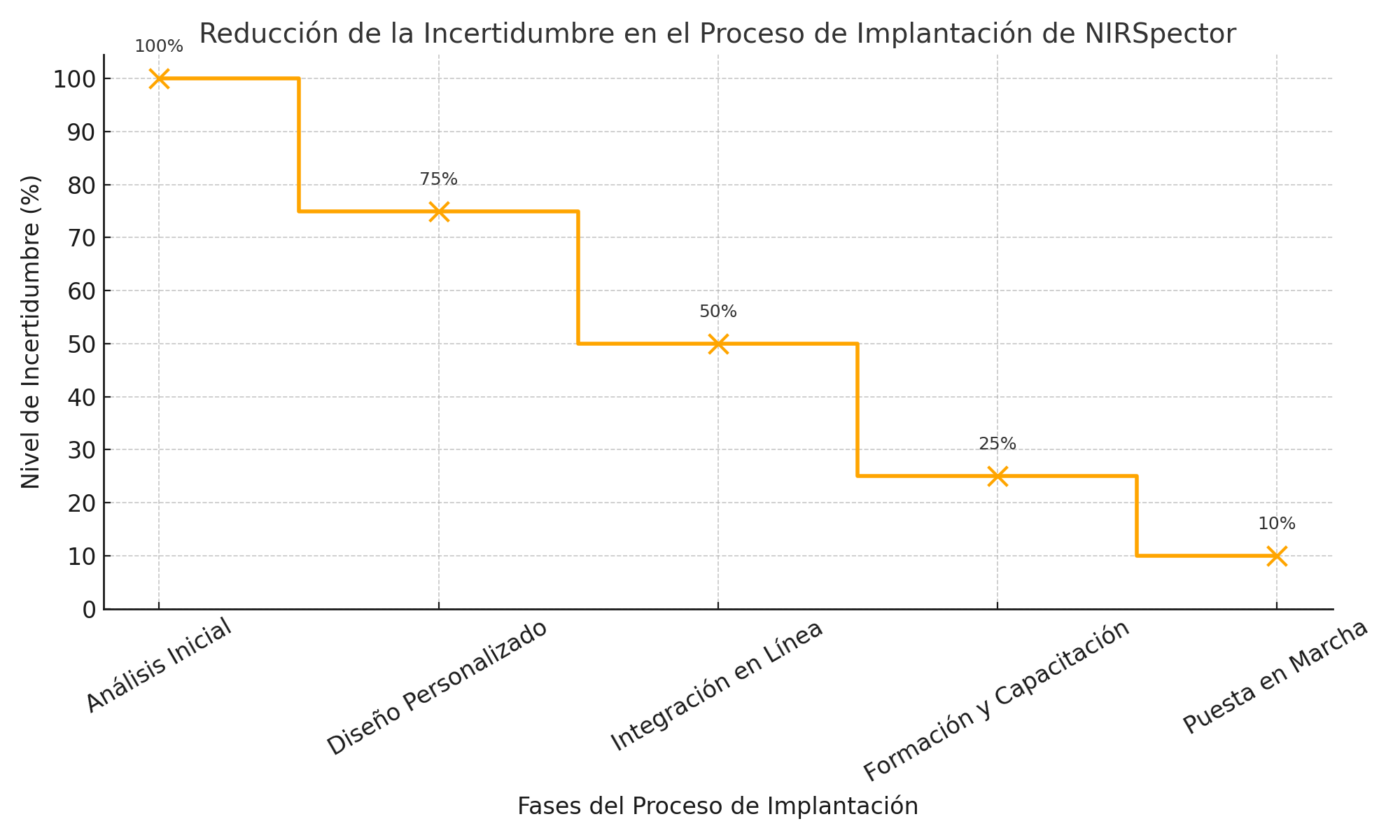

04_ Implementation

Fast, flexible and simple

NIRSpector fits seamlessly into your production line without interruptions or technical complications

The implementation of NIRSpector has been designed to integrate easily and efficiently into any production environment, eliminating uncertainties through a sequential process. Our solution is modular and highly adaptable, allowing companies to start getting results from day one without impacting their daily operations.

Initial analysis

Initial analysis

- Among its advantages are evaluation of the current production line and definition of critical control points, the ability to extract large volumes of data in real time, significantly improving the speed and accuracy of information analysis.

- Identifying processes where NIRSpector maximizes value.

Customized design

Customized design

- Configuration of NIR sensors and software adapted to the specifications of each product.

- Development of customized machine learning models based on initial customer data.

In-line integration

In-line integration

In-line integration

In-line integration - In-line installation that requires very little space.

- Seamless connection with existing systems such as MES and ERP for real-time data management.

Training and education

Training and education

Training and education

Training and education - Training for staff on system use and data interpretation.

- Continuous technical support.

Start-up and optimization

Start-up and optimization

- Start of operations with initial monitoring to adjust settings.

- Periodic review to optimize system performance according to customer needs.

Benefits of implementation with NIRSpector

Technology validation

Fase previa para validar la correcta adaptación de la solución al reto presentado.

Reducción del tiempo de preparación

Our modular technology enables fast and efficient deployment.

Continuous Support

A team of specialists ensures that the solution works optimally all the time.

Scalability

Simple adaptation to future changes in products or processes.

Results that speak for themselves

Leading companies are relying on NIRSpector for quality assurance

Solutions

Solutions

- Fresh fruit maturity analysis, reducing losses.

- Optimization of cheese production processes, increasing efficiency.

- Improved consistency in liquid cosmetics through real-time adjustments.

- Advanced oxidation control in premium wines, increasing their shelf life.

- Characterization of industrial waters for classification prior to treatment at the wastewater plant.

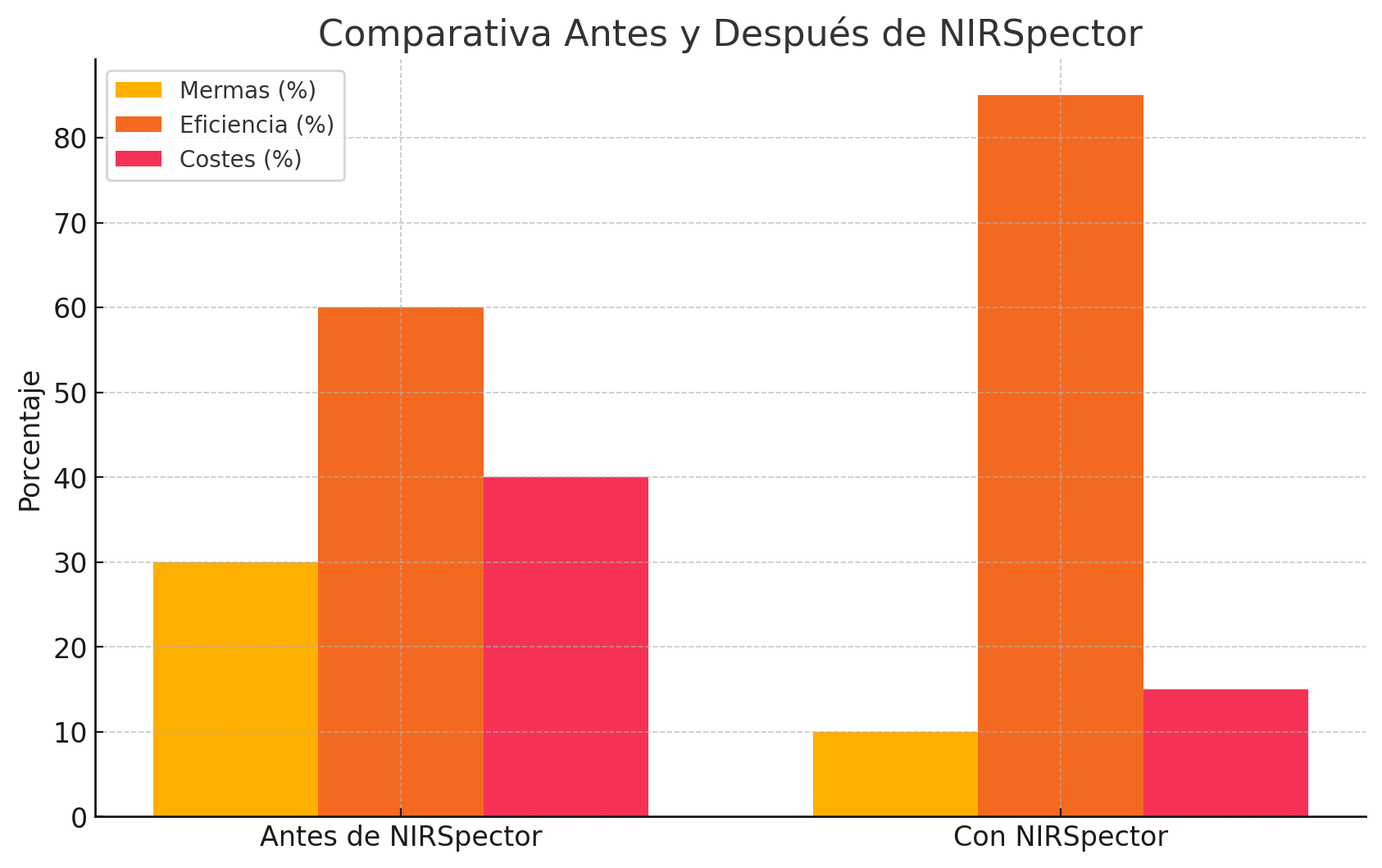

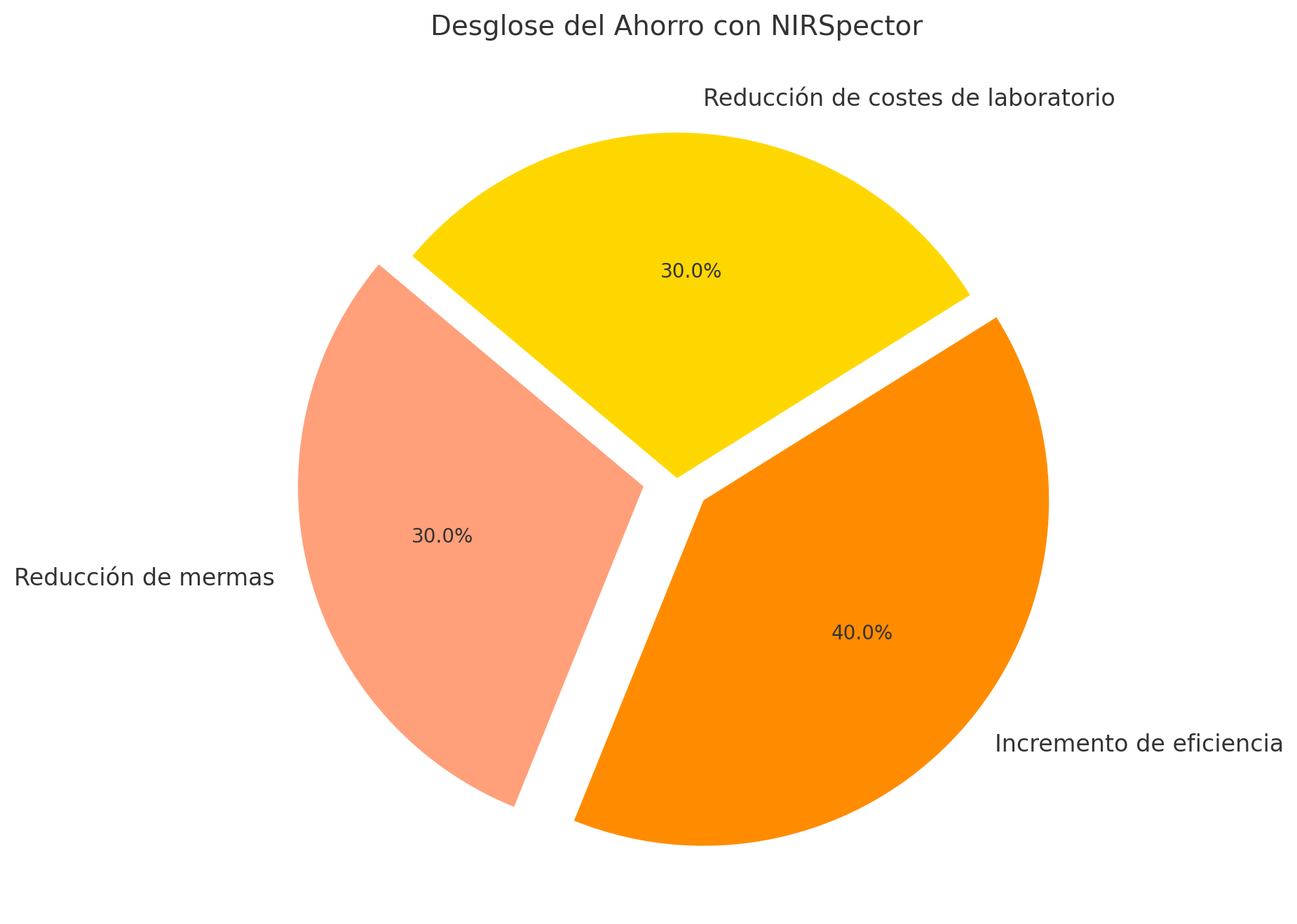

A smart investment with immediate results

NIRSpector maximizes your return by reducing waste and optimizing processes

- Save up to 30% on laboratory costs.

- Reduce losses by 30% through early detection of anomalies.

- Increases production efficiency by 40% by automatically adjusting processes.

You may be interested in

Robotization and automation

Robotics and predictive systems for resource management and optimization

Environment monitoring and analysis systems, collaborative platforms and chain management.

FoodAlert

07_ Contact us

Carlos Fernandez

Business Development

How can we help you?

Carlos Fernandez

Business Development

Basic information on data protection

Responsible

AINIA

Address

Street Benjamín Franklin, 5 a 11, CP 46980 Paterna (Valencia)

Purpose

To attend, register and contact you in order to solve the request you make through this contact form.

Legitimation

Your data will be processed only with your consent, by ticking the box shown in this form.

Addressees

Your data will not be disclosed to third parties

Rights

More information

More information is available in our Privacy Policy.

DPD

If you have any doubts about how we will treat your data or you would like to make a suggestion or complaint, please contact the Data Protection Officer at [email protected] or by filling out the form for the attention of the interested party.